All articles - Polymer Science

-

The cement industry is currently making various efforts to reduce CO 2 emissions. The blended cement produced by lowering the amount of clinker with using mineral additives has expanded as the trials to reduce CO 2 emission as well as to utilize its advantageous properties. And standards related to blended cement have been already set in all regions of the world. It is evaluated and reviewed the standards of blended cement according to the types and usage ratios of mineral additives that can be blended, which are covered by the European Standard (EN 197 1:2011), the Euro-Asian Standard (ГОСТ 31108-2020) and the U.S. Standard (ASTM C 595-16), respectively. In accordance with the blended cement standard established in each region, it is necessary to promote and expand the use of blended cement to reduce the CO 2 emission currently facing as well as to utilize various advantages of using blended cement.

-

Тонкопленочные вакуумные покрытия как средство модификации оптико-физических свойств архитектурного стекла. Перспективы промышленного внедрения в Республике Узбекистан

Green chemistry and sustainable developmentСочетание механических и оптических свойств стекла издавна определияет безальтернативность применения этого материала в самых разных областях. По мере внедрения современных технологий, когда от элементной базы изделий потребовались особые узкоспециализированные свойства, оказалось, что универсальность традиционного стекла перестала быть его преимуществом.

-

Исследование процесса подогрева нефтегазоконденсатной смеси парами легкой нафты в теплообменном аппарате 10Е04

Green chemistry and sustainable developmentДля подогрева сырья в нефтеперегонной установке используются горячие технологические потоки, выходящие из ректификационной колонны - дистилляты топливных фракций и мазута [1-4]. Для подогрева углеводородного сырья на НПЗ в основном применяют трубчатые теплообменные аппараты [2;4;5;6].

-

Physico-chemical properties of corrosion inhibition of St.3 and St.12 and the formation of mineral salt deposits.

Green chemistry and sustainable developmentCurrently, the Republic of Uzbekistan deservedly pays attention to the introduction of inhibitors to protect equipment from corrosion and scaling in production. The use of inhibitors allows several times to increase the service life of expensive equipment. In this regard, the most effective inhibitors of neutral and slightly alkaline media are nitrogen, amine and oxygen-containing organic compounds [1-3] as well as zinc organophosphonic acids, which effectively prevent corrosion and deposits of mineral salts on the surface of equipment.

-

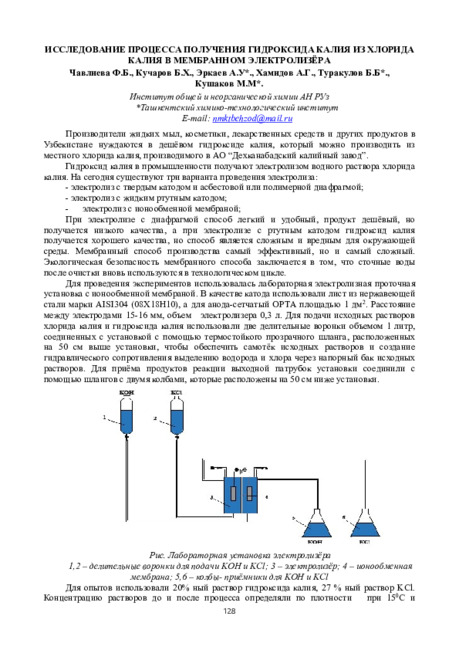

Исследование процесса получения гидроксида калия из хлорида калия в мембранном электролизёра

Green chemistry and sustainable developmentПроизводители жидких мыл, косметики, лекарственных средств и других продуктов в Узбекистане нуждаются в дешёвом гидроксиде калия, который можно производить из местного хлорида калия, производимого в АO “Дехканабадский калийный завод”

-

Extraction of ethyl acetate from secondary raw materials of the alcohol industry

Green chemistry and sustainable developmentAn important task facing the Republic of Uzbekistan is mobilizing secondary resources and fully reusing them. This issue should be considered a component of environmental protection, since it will be waste and will contaminate the biosphere.

-

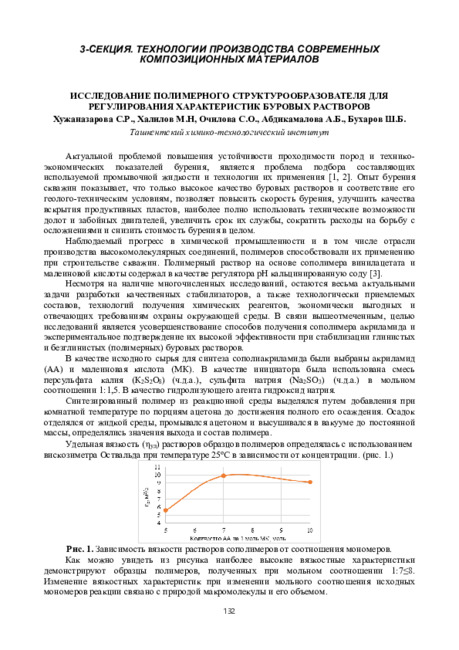

Исследование полимерного структурообразователя для регулирования характеристик буровых растворов

Green chemistry and sustainable developmentАктуальной проблемой повышения устойчивости проходимости пород и технико- экономических показателей бурения, является проблема подбора составляющих используемой промывочной жидкости и технологии их применения [1, 2]. Опыт бурения скважин показывает, что только высокое качество буровых растворов и соответствие его геолого-техническим условиям, позволяет повысить скорость бурения, улучшить качества вскрытия продуктивных пластов, наиболее полно использовать технические возможности долот и забойных двигателей, увеличить срок их службы, сократить расходы на борьбу с осложнениями и снизить стоимость бурения в целом

-

Sho'rtan gaz-kimyo majmuasi polietilen asosida uch qatlamli kompozitsion panellarning ichki qatlamini olish va fizik-kimyoviy tasirlarga chidamliligini o’rganish

Green chemistry and sustainable developmentHozirgi vaqtda jahon sanoatida polimer kompozitsion materiallar ishlab chiqarish muhim o'rinni egallaydi. Ular hayotimizning turli sohalarida keng qo'llaniladi. Yangi materiallarni ishlab chiqishga katta e'tibor beriladi. Alyuminiy kompozitsion panellar (AKP) zamonaviy qurilishda binolarning tashqi va ichki qismlarini qoplash uchun tobora ko'proq foydalanilmoqda. Yuqori plastikligi tufayli ushbu turdagi panelni osongina istalgan shaklga aylantirish mumkin va shu bilan birga, alyuminiy qotishmasining plomba moddasining kompozitsion materiali bilan birgalikda qattiqligi dinamik ta'sirning barqarorligini ta'minlaydi. Sirtning yuqori sifati, uning qoplamasi ranglarining keng assortimenti me'moriy yechimlar imkoniyatlarini kengaytirish imkonini beradi.

-

Исследование пенообразования в буровых растворах в зависимости от содержания ПАВ

Green chemistry and sustainable developmentВ данной статье исследовалось влияние содержания и природы ПАВ на процесс пенообразования в полимерных растворах. В результате эксперимента было установлено, что устойчивость пены в системе полимеров соответствует содержанию ПАВ и их пенообразующим свойствам. Кроме того, кинетика разрушения пены в полимерных буровых растворах с различными ПАВ может существенно варьировать в зависимости от структуры и природы используемых ПАВ. Также было выявлено, что концентрация ПАВ в растворе и наличие соли (CaCl 2 ) существенно влияют на кинетику образования и разрушения пены. В целом, результаты исследования позволяют более эффективно управлять процессом пенообразования в полимерных растворах и использовать полученные знания для оптимизации технологических процессов в различных областях промышленности.

-

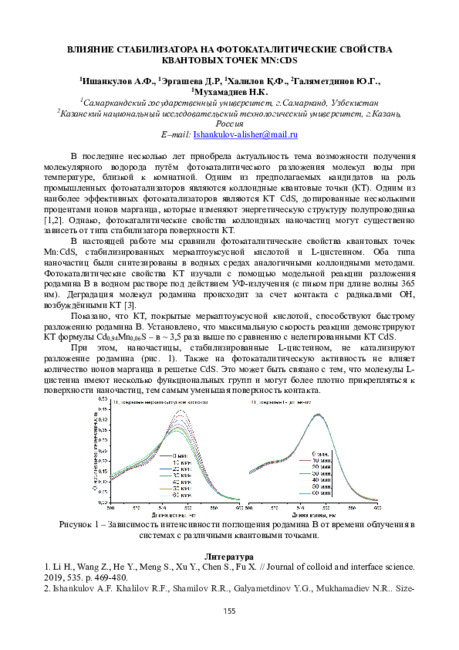

Влияние стабилизатора на фотокаталитические свойства квантовых точек MN:CDS

Green chemistry and sustainable developmentВ последние несколько лет приобрела актуальность тема возможности получения молекулярного водорода путём фотокаталитического разложения молекул воды при температуре, близкой к комнатной. Одним из предполагаемых кандидатов на роль промышленных фотокатализаторов являются коллоидные квантовые точки (КТ). Одним из наиболее эффективных фотокатализаторов являются КТ CdS, допированные несколькими процентами ионов марганца, которые изменяют энергетическую структуру полупроводника [1,2]. Однако, фотокаталитические свойства коллоидных наночастиц могут существенно зависеть от типа стабилизатора поверхности КТ.

-

Polimer kompozitsion mаteriаllаr uchun to‘ldiruvchi tаnlаsh

Green chemistry and sustainable developmentBugungi kunda to‘yinmagan poliefir smolalar asosida olingan kompozitsion materiallar xalq xo‘jaligining deyarli barcha sohalarida ishlatib kelinmoqda. Bularga misol qilib mashinasozlik, qurilish, kimyoviy texnologiya, lak-bo‘yoq sanoati va boshqa ko‘plab yo‘nalishlarni aytish mumkin. Ular asosida yana uy-ro‘zg‘or buyumlari, santexnika jihozlari, bezak mahsulotlari va boshqa o‘nlab mahsulotlar ishlab chiqarilmoqda.

-

Development of phosphorus and nitrogen-phosphoruse complex fertilizers production technology basing on Central Kyzilkum phosphorites

Catalog of abstractsTopicality and demand of the subject dissertation. One of the most topical problems in the world is the rapid development of agriculture and its needs in mineral fertilizers. Through the use of mineral fertilizers 40-50% increase in crop’s yield on average is provided.

Uzbekistan has a large chemical industry to ensure the needs of agriculture in nitrogen, phosphate and potash fertilizers. In the Republic the products range of enterprises producing phosphorus fertilizers, consists mainly of complex nitrogenphosphorus fertilizers. They are widely used for bringing in with the sowing and fertilizing. The phosphorus fertilizers are mostly effective when they are used just under autumn plowing. Therefore, the development of new technology of single concentrated phosphate fertilizers is an important task.

The complex nitrogen-phosphorus fertilizers’ production requires modernization. The fact is that their manufacture is based on the decomposition of sulfuric acid to yield the phosphate raw phosphoric acid. At the same time phosphogypsum as industrial wastes is generated. Therefore, the current phosphate processing, in which instead of gypsum a calcium nitrate is formed being effective fertilizer, especially in saline soils, becomes an urgent deal. Processing of calcium nitrate into the liquid fertilizer as the cheapest form of mineral fertilizer becomes urgent too.

The development of a thermostable form of ammonium nitrate is also an urgent problem of the chemical industry. In Uzbekistan, the ammonium nitrate is produced in quantity of more than 1 million 700 thousand tones per year. Because of the explosions in violation of the safety of its production and storage of the task is stated to create on the basis of ammonium nitrate the fertilizer, preserving its agrochemical efficiency with significantly greater resistance to external influences and therefore at risk of explosion.

The present research is focused on the implementation of the resolutions of the President of the Republic of Uzbekistan the №PR-1442 dated December 15, 2010 y. «On the priorities of industrial development of Uzbekistan in 2011-2015» and the №PR-2151 dated March 14, 2014y. «On measures to ensure agricultural fertilizers in 2014 year», aimed at accelerating the introduction to the industries of modern scientific achievements and advanced innovative technologies, the expansion of markets for products based on the diversification of production, increase of production of export-oriented, competitive industrial products based on in-depth and high-quality processing of domestic raw materials, as well as the provision of agricultural fertilizers.

On this basis, to solve the above mentioned problems it requires to carry out new researches and developments, aimed at involving into the processing of poor phosphate raw materials, to upgrade technology of complex nitrogen-phosphorus fertilizers, to increase the production of phosphate fertilizers, to expand their range of production, to reduce their costs, as well as to establish of export-oriented thermostable ammonium nitrate’s development.

Purpose of research is to develop technologies for the production of single phosphate fertilizers, nitrogen-phosphorus and nitrogen-calcium liquid fertilizers, thermostable ammonium nitrate by using the Central Kyzylkum low-grade phosphate raw materials.

Scientific novelty of the dissertation research consist in the following:

the optimum conditions of the interaction processes of low-grade Central Kyzyl Kum phosphorites with phosphoric acid gypsum slurry are studied and the technology of the single phosphorus fertilizers was created;

the liquid nitrogen-calcium and solid nitrogen-phosphorus-calcium fertilizers are produced by mean of removing calcium nitrate from nitro-calcium phosphate pulp that obtained decomposition Central Kyzylkum phosphorites with nitric acid. The correlation between the composition and properties of liquid nitrogen-calcium fertilizers depend on the norm of nitric acid and the weight ratio of nitrate ammonium calcium solution to ammonium nitrate, urea and a solution of urea-ammonium nitrate was revealed;

it was determined that the phosphate additive does increase the temperature of modification’s transformation of ammonium nitrate IV —» 111, does decrease thermal effects of modification’s transactions, does increase decomposition temperature on 29-39°C, does reduce crystal sizes of fertilizer’s granules, as the result the thermal stability of nitrogen-phosphorus fertilizer does increase;

the technology of novel fertilizers containing of assimilable forms of P2O5 and CaO on the basis of introduction of various types of high calcareous Central Kyzylkum phosphorites into ammonium nitrate melt was created.

Conclusion

The thesis contains the solution of very relevant scientific and technical problems in the field of chemistry and chemical technology of mineral fertilizers, laying a theoretical and applied research, ensuring development of resource-saving technology for new types of single phosphorus, nitrogen-phosphorus and liquid nitrogen-calcium fertilizers based on complex processing of the Central Kyzylkum phosphorites.

The main scientific and practical results obtained in the performance of the thesis are as follows:

1. The study of graphoanalitical analysis of CaO^Os-SOs-fTO and CaO-P2O5-N2O5-H2O systems has theoretically proved the process of interaction between the Central Kyzylkum phosphorites with phosphoric acid-gypsum pulp and nitric acid with reduced norm. New scientific evidence obtained allows to justify and to predict the flow conditions and processes of single nitrogen-phosphorus-calcium fertilizers during the processing of Kyzylkum phosphorites and to find optimal compositions.

2. The interaction between different types of the Central Kyzylkum phosphorites and a phosphoric acid gypsum pulp obtained by the decomposition of washed calcined concentrate with sulfuric acid, in the range of mass ratios PAGS:PR = 100 : (25-70) was investigated. Ratios and concentrations limits of the reactants involved in the process were established. It is shown that the optimal ratio of PAGS:PR is 100 : (25-30), in which single fertilizer with a maximum content of digestible and water-soluble form of P2O5 and CaO can be obtained. To improve the marketable properties of the product in sulfo-calcium phosphate slurry it is recommended to add the sour runoff - absorption solution of EPA production.

3. The advanced technology of nitrogen-phosphorus-calcium containing and liquid nitrogen-calcium fertilizer production by partial release of calcium nitrate from ammoniated nitrogen-calcium phosphate slurry by various options was developed. Il is shown that in the proposed NPCa fertilizers content of P2O5 is 7-10% higher than in NCPF (nitrofos), which is produced at JSC «Samarkandkimyo».

The studies have been conducted on the processing of NACS, which is the liquid phase of nitrogen-calcium phosphate slurry, in various marks of LNCF. The different composition of LNCF was obtained with evaporation method of NACS and neutralization with ammonia depending on the norm of nitric acid. And by adding ammonium nitrate, urea and CAN solution to NACS a wide range of LNCF with high nitrogen content was obtained.

4. The possibility of obtaining of NPF on the basis of interaction of different types of the Central Kyzylkum phosphorites with a melt or concentrated solution of AN was studied. The kinetics of decarbonization and activation of ordinary phosphorite flour in AN melt were studied. It is shown that a high degree of decarbonization and activation of phosphate raw materials in NPF observed after 20 minutes of initial regents’ interaction. It was found out that the introduction of phosphate additives into ammonium nitrate significantly increases the hardness of granules, i.e. on average for 2.0-5.5 times. Adding phosphorite powder to an amount of 5% in terms of P2O5 to AN melt reduces porosity of its granules from 9.15 to 7.08%. Caking of NPF containing 3.0-5.04% P2O5 is 1.71-1.87 kg/cm2 that 2.5-2.7 times less than the net AN caking.

5. The effect of phosphate additives on the modificational conversions of ammonium nitrate was studied. Determined that for AN transformation temperature IV—>111 is 44.8°C, and with the addition of phosphate raw materials in the amount of 1.05-5.04% P2O5 to AN the temperature of this transformation increases from 53.7 to 56.6°C. This reduces the melting temperature and crystallization of AN. Rising the transition temperature IV —> 111 contribute to the preservation of high strength and to reduction of NPF granules caking during transport and storage in hot climates.

Thermal effects of modificational transitions of NPF were defined. It is shown that their values are much lower than the initial AN’s heat of transition. Consequently, they occur with minimal thermal effects and the additive has an inhibitory effect on modificational transformation and at the transition points of transformation does not proceed until the end, and that helps to reduce the level of granules’ destruction, sealing their structure and thus the preservation of increased strength.

6. It was shown that when AN is heated the phosphate additives have beneficial buffering action and stabilize its pH value. The temperatures of the beginning of their decomposition and energy of their activation process were determined. It was found out that the onset temperature of thermal decomposition of the AN as part of NPF compared to net AN depending on the amount of phosphorite additives, increased from 29 to 39°C. It is shown that the activation energy of NPF decomposition, containing from 1 to 5% P2O5 varies between 46.6-51.6 kcal/mol, which is 4.7-9.7 kcal/mol higher than the activation energy of pure AN decomposition. This indicates a significant increase in thermal stability of phosphatized AN.

Conducted electron-microscopic study of micro-structures of NPF granules shows that the phosphate additive reduces the size of ammonium nitrate crystals. Phosphorite settles into the pores and microcracks, filling them, forming a more perfect surface and internal structure of the NPF granules.

By conducting of pilot tests in the workshop number 3 at JSC «Navoiazot», the losses of ammonium and nitrate nitrogen at release of developed nitrogenphosphorus fertilizer were identified. Losses per 1 t of NPF were: in the form of NIL - 0.52 kg/t, and in the form of NH4NO3 - 0.41 kg/t, i.e. overall loss at the mixing and granulation stage of NPF in terms of nitrogen amounted to 0.572 kg/t which is the allowable value.

7. Physicochemical and rheological properties of solutions, pulps and melts which were formed at various stages of technological process of the Central Kyzylkum phosphorites processing were determined. With the use of X-ray methods and 1R spectroscopic analysis the salt composition of the products was established, also the physicochemical and product properties of single, nitrogenphosphorus and NPCa fertilizers were studied.

8. Based on the results of the laboratory experiments, data of tests carried out at the model installation and at a pilot works the technological scheme was designed and material balance of production of singles, nitrogen-phosphorus, NPCa and liquid nitrogen-calcium fertilizers was composed. The results of the physical, chemical and applied researches on the decomposition of the Central Kyzylkum phosphorites with phosphoric acid-gypsum pulp formed the basis for the development of technology for single-phosphorus fertilizer, which has been successfully tested at JSC «Ammofos-Maxam» with the release in 2009 of 60 tons, and in 201 1, 100 tons of a new type of fertilizer. Production technology of NPF based on ammonium nitrate melt and the Central Kyzylkum phosphorite flour is implemented at JSC «Navoiazot». Since the beginning of 2009 to the present time more than 300 thousand tons of new type of NPF in the amount of 165 billion soums were produced.

9. Technical and economic calculations were fulfilled for the single, NPCa and liquid nitrogen-calcium fertilizers. In organizing the production of single phosphorus fertilizer the norm of sulfuric acid per 1 ton of 100% P2O5 compared to the production of suprefos reduced to 30-35%. Wholesale price of granular NPCa fertilizer is 565511 soums compared to NCPF on 118643 soums cheaper. Wholesale price of LNCF, which is obtained with the addition to NACS ammonium nitrate and urea is 192722 and 285548 soums respectively. With the release of 100 thousand tons of NPF per year only due to the absence of special protection and support more than 2 billion soums are saved.

10. Agrochemical tests of derived fertilizers at cotton plants’ fields in the microlysimetric, pushed plot and field conditions were held. These results indicate that the efficiency of the developed agrochemical fertilizers is close to the efficiency of mixtures of traditional fertilizers with an equivalent amount of nutrients. -

Some ways of phospholipids transformation in cotton seeds and in the seeds of higher plants during their growing and ripening

Catalog of abstractsSubjects of inquiry: Seeds and seedlings of cotton (Gossypium hirsutum L.), sort 108-F (AD/); soybean (Glycina hispida Li), sort Dustlik, arahis (Arahyus hypogaea L), sort Persuvan 46/2, cereal (Triticum aestivum L.), sort Una, mays (Zea mays L.), sort BC-6661, pea (Phaseolus vulgaris L.), sort Vigna, stamped 661, vegetative and generative components of cotton seeds.

Aim of the inquiry: To study some ways of phospholipids transformation in cotton seeds and in the seeds of higher plants during their growing and ripening stages.

Method of inquiry: The extraction of the phospholipids was carried by Davson’s and Hemitong’s methods, the quantity of phospholipides was defined by method of Tauski and Shora as well as by Vaskovskiy’s method, the quantity of proteins was identified by Louri’s method, the content of phospholipids was defined by Keyts’s method in ThLCh.

The results achieved and their novelty: For the first time the research of essential cotton seed’s phospholipids along with seeds of some higher plants (cereal, arahis, soybean, pea and mayz) was carried out during their development from seed to seed and common ways of phospholipids transformation were shown.

It was shown that phospholipase D due to its hydrolase and transferase functions actively takes part in plastic metabolism during cotton seeds’ growing and ripening stages. In vivo and in vitro investigations defined phosphatidil methanoic, which is produced because of transferase function of this enzyme and hasn’t been found in plants yet. Fitase plays a great part in manifesting transferase activity of phospholipase D as fitase delivers inosit. Some models of bicnzimatic systems with fitase and phospholipase were created. These systems could be used in practical aims.

Practical value: The results of these investigations could be used in producing of some valuable prcparatcs such as phosphotidilinosit and mioinosit. They arc very perspective in medicine and pharmacology.

Degree of embed and economical effectivity: The method of preparate production could be used in practice. Some results arc used in special training programs at Universities.

Sphere of usage: Scientific researches, educational process in Higher Educational Institutes. -

Subjects of the inquiry: basaltic rock of Kutchi deposit, kaolin from Angren deposit, alumina-containing waste of Shurtan gas-chemical complex.

Aim of the inquiry: development of glass and glass-ceramics on the basis of basaltic rock from Kutchi deposit for the building-facing assignments and investigation of their properties.

Methods of inquiry: chemical, mineralogical, X-ray diffraction, electron microscopy, differential thermal analysis, infrared spectroscopy, etc.

The result achieved and their novelty: in the present work, a phase transformation of Kutchi basalt, which occurs at the temperate range from 200°C to its complete melting, was firstly investigated in detail.

- melting temperature of Kutchi basalt was firstly studied;

- phase transformation of Kutchi basalt at high temperatures was investigated using X-ray diffraction and infrared spectroscopy;

- a glass based on basaltic rock from Kutchi deposit was obtained;

- formation mechanism of anorthite phase under ccramization process of the glass was elaborated on the dependence of thermal treatment conditions and crystallization.

- glass-ceramics, which crystallize at the temperatures of 900-1100°C, were obtained;

- physico-mcchanical and chemical properties of obtained glass and glassceramics were determined.

Practical value: production possibility of chemical resistant tiles and facing tiles on the basis of Kutchi basalt for the placement, where chemicals influence, and building construction, respectively, was proven.

Optimal composition and temperature - time conditions for the preparation of decorative facing materials and chemical resistant glass-ceramic tiles were developed on the basis of investigation.

Degree of embed and economic etfectivity: developed optimal compositions of glass and glass-ceramics were tested in the conditions of ОАО «ONYX» end Almalik ОАО «Ammafos».

Sphere of usage: chemical resistant facing tiles can be used for chemical apparatuses and buildings. -

Obtaining and physical-chemical properties of nitrogen -and phosphorus containing ionites on the base of polyvinylchloride

Catalog of abstractsThe urgency and relevance of the theme of dissertation. Nowadays applying of state-of-the-art technologies is becoming a very urgent task to face ecology and climate challenges due to fast development of various branches of industry and energy production, and also to be able to meet competition in the market. It is especially noticeable in such activities as desalination of natural water for industrial usage, extraction of precious metals from process solutions, wastewater treatment by ion-exchange technologies. «For the past years the need for technology solutions based on ion-exchange has been increasing. A considerable part of materials used for water purification is ion-exchange resins»1.

Starting from the very beginning of our independence, in Uzbekistan all required conditions have been creating for industrial development and new nonwaste productions of competitive, ecological and import-substituting goods arc creating. We can name some of them - «Shurtan Gas Chemical» and «Ustyurt Gas Chemical», producing polymers using local raw materials, and a new chemical plant which is creating at «Navoiyazot Ltd» and expecting to be completed in 2017 with annual production of 100000 tons of polyvinylchloride (PVC). It makes possible to difersify chemical industry by creation of production of various polymer materials having different and complex properties.

Developing and increasing of industrial production over the world creates new demands for sorbent materials, especially targeted rcascarchcs on synthesizing sorbents having complex properties arc one of high-priority tasks and the following aspects arc of high interest: obtaining ion-exchange materials having complex properties and contatining acidic as well as basic groups, determining the selectivity of synthesized sorbents for precious, rare and nonferrous metals, waste water treatment by removing toxic and heavy metal ions.

--------------J------ -----------------J-----------

The study aimes particularly at solving tasks defined in President’s Decrees №916 dated 15 July 2008 «On additional measures to stimulate innovation rpojects and technology implementation into production» and №1071 dated 11 March 2009 «On measures to accelerate creation and adoption of production of new types of chemical products» and oter relevant legal documents.

Purpose of research work: is synthesizing anionites and polyampholitic resins containing nitrogen and phosphorus groups by modifying polyvinylchloride and studying the physical and chemical properties of obtained products.

Scientific novelty of the research work consists of:

Optimal conditions for synthesis of anion-exchange resin using granular polyvinylchloride as a substrate have been determined for the first time; it has been shown that reaction depends on porosity of modified polyvinylchloride structure and follows under heterogeneous reaction kinetics rules;

ion-exchange resin containing nitrogen and phosphorous groups and having polycomplcxon properties has been synthesized by modifying granular polyvinylchloride based anionite with phosphorous acid; optimal conditions for this process have been developed;

it has been found that synthesized ionites have high sorption efficiency, thermic and mechanical resistance and arc similar to those of commercial anionite AN-31 in terms of abovementioned characteristics;

high sorption factors of synthesized anionites and polycomplexons for chromate, copper, vanadium, nickel, indium ions and iodine have been found and metal ions have been extracted in dynamic conditions from complex solution containing copper (II), nickel (II), zinc (II), cobalt (II) and high selectivity of polyampholitic resin for Cu(II) ions has been found.

CONCLUSIONS

The following conclusions on doctoral dissertation «Obtaining and physicalchemical properties of nitrogen- and phosphorus containing ionites on the base of polyvinylchloride» arc represented:

1. The impact of several factors on a modification process of granular polyvinylchloride with polyethylene polyaminc as well as on condensation process with phosphorous acid in the presence of formalin has been studied in order to produce anionite and nitrogen- and phosphorous containing polycomplcxon. The value of activation energy and dependence of reaction rate only on concentration of low-molecular reagents show that the studied processes run in accordance with the rules of heterogenic reactions.

2. Chemical structure of anionit and polycomplexons produced on the base of granular polyvinylchloride, their chemical and thermal resistance have been proved by IR-spcctroscopy, element analysis, thermic analysis and analytical methods. It has been determined that appearance of ion-exchange features of anionite is due to amine groups and of plycomplcxon is due to amine groups and residues of phosphorous groups.

3. The main physical and chemical properties of obtained anionites and polyampholytes, defined in official standards, have been examined in laboratory and industrial conditions and it has been represented that synthesized anionite is not worse than AN-31 commercial anionite which is used in industry.

4. Kinetics and thermodynamics of a sorption process of Cr2O2'7 ions and iodine from potassium iodide solution by anion-exchange resin synthesized from granular polyvinylchloride has been studied. Defined kinetic and thermodynamic parameters show high affinity of anion resin to dichromate ions and molecular iodine and its resistance to the influence of strong oxidizers.

5. The following order of selectivity for non-ferreous metals: Cu(II)>Ni(II)>In(III)> vanadyl(I) has been defined by studying kinetics and thermodynamics of absorption of Cu(II), Ni(II), In(III) and vanadyl(I) by polycomplcxon.

6. Sorption and desorption of Cu(II) and In(III) by synthesized polycomplcxon in dynamic condition have been examined. Obtained results demonstrate chemical stability of polycomplcxon and its repeatedly usage has been recommended. Containing nitrogen and phosphorus polycomplcxon has been successfully used to extract and concentrate indium selectively from complex technological solution of Zn producing plant of «ОММС» JSC company.

7. Granular anion resin on the base of polyvinylchloride has been synthesized in large amount using a pilot device at «MAXAM-CHIRCHIQ» company and used for effective desalination of natural waters. The anion resin was able to work 10-15% longer than competitive anion resin. It is recommended by Notification Letter №42 of Cabinet of Ministers to invest one billion sums by «MAXAM-CHIRCHIQ» company JSC on production of PPE-1 anion resin.

8. A high efficiency is achieved in using anion resins to remove impurities of thermic stable salts from mcthyldicthanolaminc that is used for cleaning converter gases in «Fargonaazot» company (Reference Letter of «Fargonaazot» №37/3768, dated 26 July 2016). The annual cost efficiency has been estimated as 10 million sums.